nPro: Heat pump design and sizing tool

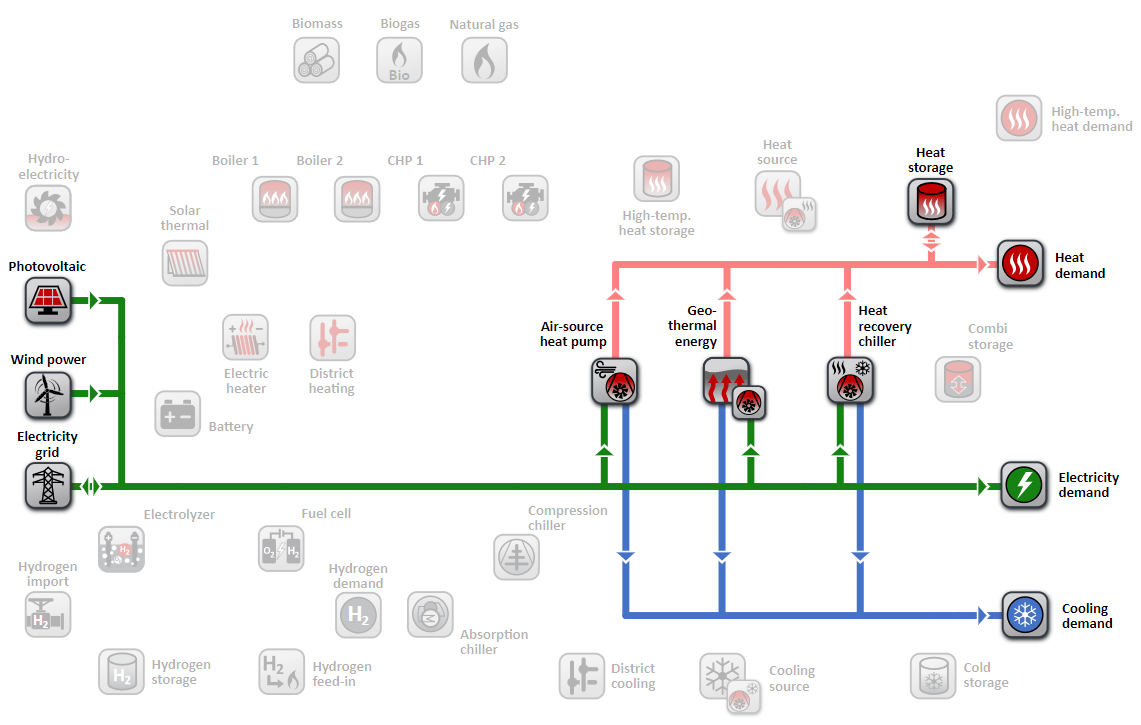

Heat pumps play a central role for future energy systems, as they represent an efficient interface between the electricity and heating sectors. The challenging planning and dimensioning process of heat pump systems can be best addressed with appropriate software tools.

Planning of large-scale heat pumps

Large heat pumps are crucial to supply districts and heat networks: They enable the efficient conversion of surplus electricity in the power grid into heat. Heat pumps are ideally fed by renewable energies and combined with heat storages. Storing heat is much more efficient from an economic point of view than storing electricity, in batteries for example. Heat pumps with heat storages can efficiently use generation peaks of renewable energies (photovoltaic or wind turbines) and avoid renewable energies being curtailed. Large heat pumps are often installed to supply heat grids: There are already countless examples of applications worldwide in which heat pumps contribute to a climate-neutral heat supply for districts and urban areas.

Heat sources for large heat pumps

When choosing a suitable heat source for large-scale heat pumps, a variety of different options are possible: A typical example for urban areas is waste water heat. Heat exchangers are installed in sewers to extract heat from the waste water. The advantage of waste water heat is that high temperatures of around 12 °C are available all year round. High source temperatures lead to a high heat pump efficiency (coefficient of performance, COP). These heat pumps typically feed low-temperature heat networks that supply heat to surrounding neighborhoods. Another heat source is river water: River water usually has year-round temperatures above 0 °C and is therefore also suitable as a heat source. The advantage here is that many large cities have at least one river, which offers great potential for decarbonizing the heat supply. Depending on the flow temperature of the heat network, high coefficients of performance can be achieved and, due to economy of scale, a profitable operation can be realized. Numerous other heat sources can be used for heat pumps, for example subway shafts, waste heat from cooling processes (food industry or data centers), but also typical heat sources like ambient air (air-source heat pump) or geothermal energy (ground-source heat pump).

Tool for dimensioning heat pumps for heat networks

In order to estimate the economic efficiency of a heat pump, it is crucial to do design calculations based on an entire design year. For this purpose, simulation calculations are often carried out, but alternatively, so-called mathematical optimization models can be used. Mathematical optimization models make it possible to determine the system configuration that achieves the best result in terms of economic efficiency. With the help of the nPro tool, these design calculations can be carried out with just a few clicks. Ecological factors (CO2 emissions) can also be taken into account. For this purpose, a CO2 price can be taken into account, which leads to more ecological system designs. Mathematical optimization models have numerous advantages over simple Excel calculations: First, they can simulate the energy system with a high temporal resolution and thus account for fluctuating renewable energy generation profiles. On the other hand, they consider an entire design year, which helps to include different operating behaviors in different months and thus, size the components not only according to peak loads.

Designing efficient heat pump systems

The decisive advantages of heat pumps over combustion technologies such as boilers or CHP units are, on the one hand, their high thermodynamic efficiency and, on the other hand, the possibility of providing not only heat but also cooling. However, some factors have to be taken into account for an efficient use of heat pumps: First, the temperature lift, i.e. the difference between source and sink temperature, must be as small as possible. The smaller the temperature lift, the higher the coefficient of performance (COP) and the lower the electricity input per kWh of delivered heat. Since heat pumps have comparatively high investment costs, the heat pumps operation should result in high full load hours. For peak load coverage in winter, other systems such as power-to-heat boilers can be installed which have lower investment costs. Another influencing factor are cycle times: A heat pump should not be switched on and off too often, as each start-up process leads to wear of the mechanical components (e.g. compressor). Ideally, a heat pump should therefore be operated for several days at a time. To increase the cycle times, heat storages and intelligent predictive controls can be used. In order to exploit the full potential of a heat pump, the heat pump should be designed in such a way that - if possible - both heat flows at the hot and cold ends can be used: While the useful heat flow occurs at the condenser of the heat pump at a high temperature level, a cold flow occurs simultaneously at the evaporator, which can also be used. Optimally, both sides of the heat pump can be used directly to meet simultaneous heating and cooling demands. In this case, the heat pump achieves very high coefficients of performance (heat output plus cooling output divided by electricity input). Such heat pumps are also called heat recovery chillers, since they provide cooling energy and use the resulting waste heat directly for other processes. In addition to ground-source and air-source heat pumps, the nPro tool can also be used to dimension heat recovery chillers and investigate their influence on the overall performance of the system.

This might also interest you

nPro software

Plan your energy system with nPro!

English

English

Deutsch

Deutsch